WARNING: This product contains nicotine. Nicotine is an addictive chemical.

Why does vape produced by disposable vape manufacturer leak e-liquid? When many vapers buy a new disposable vape, the e-liquid will leak from the bottom or the e-liquid will be inhaled out of the vape holder.

This situation will cause consumers to waste money and is not good for their health. It is also not conducive to the long-term development of disposable brands. In addition to the improper use of products by consumers themselves, the main reason is the product design and production assembly problems of the disposable vape manufacturer. Of course, this is also related to the actual production cost of disposable vape.

The most important reasons for the e-liquid leakage of disposable vapes (which process problems) are:

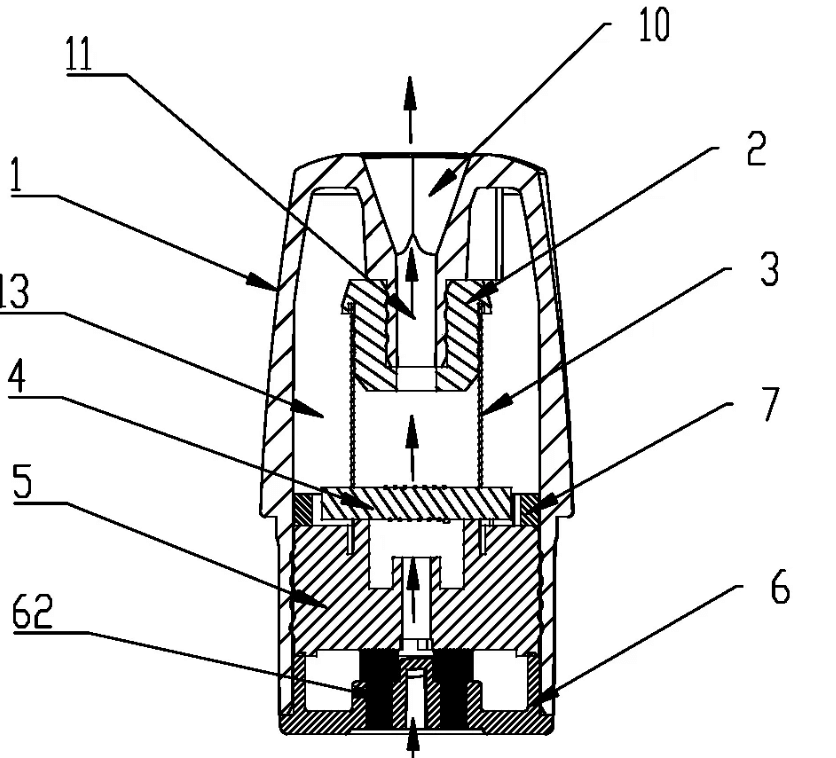

(1) Sealing problem of silicone ring;

(2) The density of e-liquid storage cotton is too small;

(3) e-liquid viscosity is too low;

(4) Structural design issues of disposable vape;

These problems are all difficulties in the design process of disposable vape, which is a very big challenge for OEM&ODM disposable vape manufacturer;

The design of a disposable vape is a very complicated and precise process. The design process of disposable vaping mainly includes the following steps.

The design process of disposable vape:

1. Industrial design

Industrial design is the first step in the birth of a good disposable vape product, and it is also a crucial step:

① Product planning:

In the product planning stage, the ODM disposable vape manufacturer first needs to communicate with the brand owner, and at the same time confirm the brand’s cost budget and product demand according to the brand’s market research results and product description;

② Appearance design:

1) CMF, at this time, it is necessary to confirm the color, material, and processing technology of the product;

2) According to customer needs, carry out product function layout;

3) Preliminary cost assessment based on CMF positioning and product functions;

4) The designer conducts a preliminary sketch design according to the information;

5) Reorganize the appearance elements and confirm the appearance sketch according to the relevant design elements and product functions;

6) Confirm the product sketch, finalize it, and confirm it to the customer;

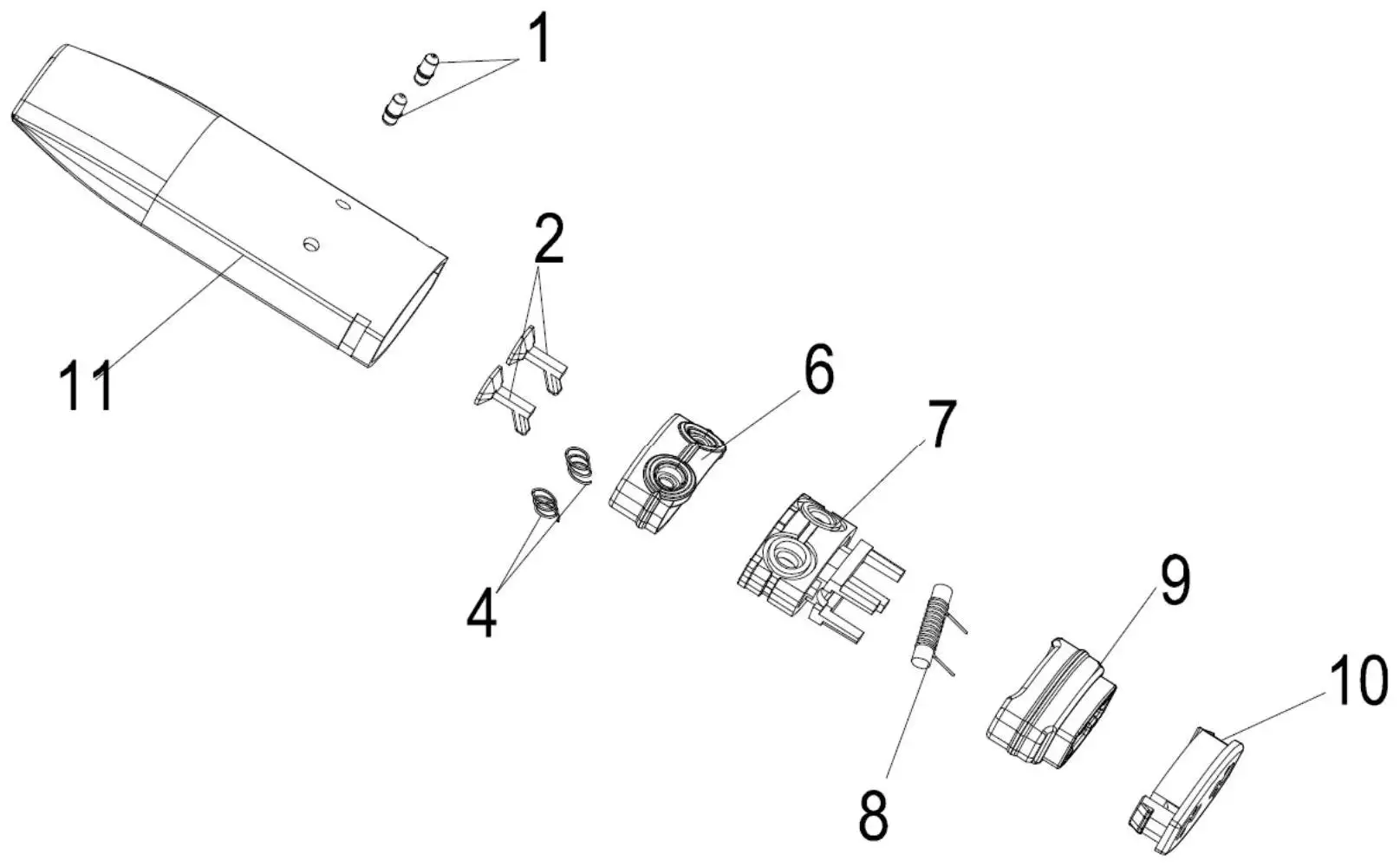

2. Internal structure design

①Confirm the material and function of the product, and analyze the feasibility;

② Estimate the cost of the internal structure;

③ After evaluating the cost, it is necessary to design each part of the internal structure:

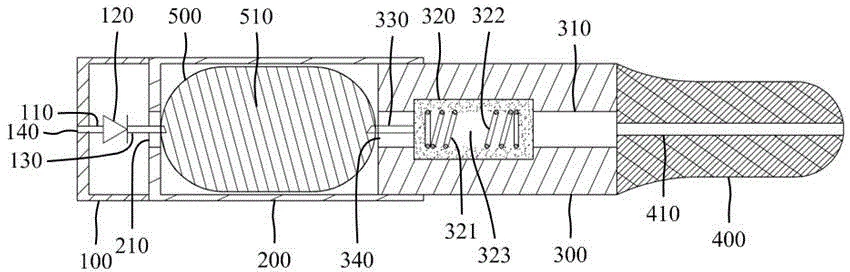

1) Design of atomization components:

The design of the atomization component needs to take into account the stability of the taste after the e-liquid is materialized, which is also the difficulty in the design of the materialization component;

2) Battery design:

There are many difficulties in battery design, and the adaptability of battery capacity, output current, and other factors need to be considered during design;

3) Sealed airway design:

Since the product needs to be tested under extreme pressure and temperature, if the sealed air passage is not well designed, the product will cause serious e-liquid leakage;

4) Matching of e-liquid:

Vape oil needs to be rigorously and repeatedly tested. When debugging e-liquid, it is necessary to closely control the material ratio and the thickness of the e-liquid, and adjust the taste to meet the fit of the customer;

3. Quality inspection

In this link, the finished product needs to be tested, and the quality inspection is also a crucial link in the last link, which is also related to the success or failure of a product. Common product tests include: negative pressure tests, high and low-temperature tests, drop tests, simulation transport tests, simulated vape tests, etc.

4. Summarize

e-liquid leakage is a serious problem for disposable vape. The quality, taste, and design of disposable vape products also determine whether disposable vape brands can open up a larger market.

Therefore, it is particularly important to choose a high-quality ODM disposable vape manufacturer. The disposable vape manufacturer needs to have first-class ID design, product design, cost control, and quality control capabilities, so as to ensure that consumers can obtain good users. Experience, the brand can gain users’ trust, and the brand can have better sustainable development.

KEYSTONE is a very professional ODM&OEM disposable vape manufacturer. Under the premise of ensuring quality, it has a very strong supply chain platform and product design capabilities. KEYSTONE team members have more than 10 years of experience in internationally renowned disposable vape brands.

If you want to know more, please refer to this article: